Premium suppliers of quality engineered wood flooring for THE FLOORING TRADE

Guaranteed warranty on all products

Sanding Belts

Choosing the Right Sanding Belt

Sanding belts are abrasive tools used in various power sanding machines to smooth and finish surfaces. They consist of a continuous loop of coated abrasive material, which is wrapped around two cylindrical drums in the sanding machine. The drums rotate, and the abrasive surface of the sanding belt moves over the workpiece, effectively sanding and removing material through abrasion.

Sanding belts come in various sizes, grits, and materials, making them suitable for different applications and materials. The abrasive material is typically made from aluminum oxide, silicon carbide, or other abrasive compounds coated onto a durable backing material like cloth or paper.

The key components of a sanding belt include:

Abrasive material

The abrasive particles on the belt are responsible for cutting and abrading the workpiece. The choice of abrasive material depends on the hardness of the material being sanded and the desired finish.

Grit size

Sanding belts are available in various grit sizes, ranging from coarse to fine. Coarse grits are suitable for heavy material removal, while finer grits provide smoother finishes.

Backing material

The backing material provides support and stability to the abrasive particles. It can be made of cloth, paper, or other materials, and its durability affects the overall lifespan of the sanding belt.

When using sanding belts, it’s essential to choose the right grit size and material to match the specific task and material being worked on. Coarser grits are used for heavy material removal, while finer grits are employed for achieving smooth finishes. Additionally, appropriate safety measures should be taken, including wearing eye protection, respiratory masks, and proper ventilation, as sanding can generate fine dust particles that may be harmful if inhaled.

When do you use sanding belts?

Sanding belts are used when you need to remove material, shape surfaces, or achieve a smooth finish on various workpieces. They are particularly effective for projects that involve large flat surfaces or require efficient material removal. Some common scenarios where sanding belts are used include:

Woodworking

Sanding belts are extensively used in woodworking to smooth rough surfaces, remove mill marks, and prepare wood for finishing. They are commonly employed for sanding wooden boards, furniture, cabinets, and other wood-based projects.

Metalworking

In metalworking, sanding belts are used for deburring, removing rust, shaping metal pieces, and refining edges. They can be used on metals such as steel, aluminum, brass, and more.

Automotive industry

Sanding belts are used in the automotive industry for tasks like sanding body panels, preparing surfaces for painting, and refinishing various components.

DIY home projects

Sanding belts come in handy for DIY enthusiasts working on home improvement projects. They can be used for sanding floors, refinishing furniture, or shaping smaller wood or metal projects.

Industrial applications

In various industrial settings, sanding belts are utilized for heavy material removal, shaping parts, and finishing surfaces in large-scale manufacturing processes.

Carpentry and cabinetry

Sanding belts are an essential tool for carpenters and cabinetmakers to achieve smooth and precise surfaces in their projects.

Difference between a zirconium sanding belt and Ali oxide sanding belt?

The main difference between a zirconium sanding belt and an aluminium oxide sanding belt lies in the type of abrasive material used:

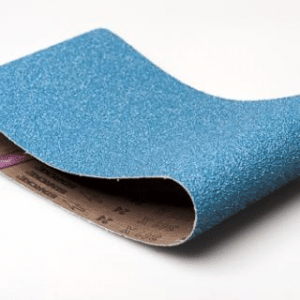

Zirconium Sanding Belt

Zirconium sanding belts use zirconium oxide abrasive grains. Zirconium oxide is a tough and durable material, making these belts well-suited for heavy-duty applications and challenging materials. They offer aggressive cutting action and are often used for grinding and stock removal on hard metals, stainless steel, and other tough surfaces.

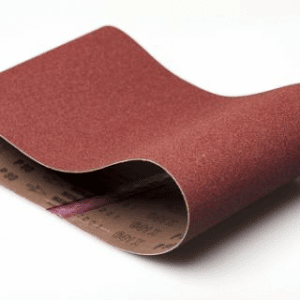

Aluminium Oxide Sanding Belt

Aluminium oxide sanding belts use aluminium oxide abrasive grains. Aluminium oxide is a versatile and widely used abrasive material known for its balance between cutting ability and durability. These belts are suitable for general-purpose sanding and work well on wood, metal, plastic, and other common materials.

In summary, the key differences between zirconium sanding belts and aluminium oxide sanding belts are related to the type of abrasive material and their specific applications:

Zirconium belts

Ideal for heavy-duty applications, aggressive material removal, and grinding on hard metals and stainless steel.

Aluminium oxide belts

Suitable for general-purpose sanding, woodworking, and working on a variety of materials, providing a balance between cutting ability and durability.

The choice between the two types of sanding belts depends on the specific material being worked on and the level of aggressiveness required for the task. For more specialized applications, such as heavy metal grinding, zirconium sanding belts may be preferred, while aluminium oxide sanding belts are well-suited for general sanding and finishing tasks.

Difference between a zirconium sanding belt and Ali oxide sanding discs

The primary difference between a zirconium sanding belt and an aluminum oxide sanding disc lies in their form and the tools they are used with:

Zirconium Sanding Belt

Zirconium sanding belts, as discussed earlier, use zirconium oxide abrasive grains and come in the form of a continuous loop that wraps around the drum of a belt sander. They are commonly used for heavy-duty material removal, grinding, and surface preparation on hard metals and challenging surfaces.

Aluminum Oxide Sanding Disc

Aluminum oxide sanding discs, on the other hand, use aluminum oxide abrasive grains and are circular discs that attach to the backing pad of a random orbital sander, disc sander, or angle grinder. They are versatile and well-suited for general-purpose sanding and finishing tasks on a wide range of materials, including wood, metal, plastic, and composites.

In summary:

The choice between zirconium sanding belts and aluminum oxide sanding discs depends on the specific tool being used and the nature of the project. Belt sanders with zirconium sanding belts are best for heavy stock removal and grinding tasks, while random orbital sanders or disc sanders with aluminum oxide sanding discs are more versatile and suitable for a broader range of applications.

Sanding belts for wood flooring contractors

Sanding belts are an essential tool for wood flooring contractors, and choosing the right type of belt for the job is crucial. The grit size of the sanding belt determines the coarseness of the sandpaper, which affects how much wood is removed with each pass. For initial sanding or removal of old finishes, a coarse grit of around 36-60 is recommended, while a finer grit of 80-120 is suitable for smoothing and preparing the surface for finishing.

It is important to note that using the wrong grit size can lead to uneven sanding, wood damage, and excessive wear of the sanding belt. In addition, the quality of the sanding belt is also critical to achieving a good finish. Choosing a high-quality sanding belt can ensure that the abrasive material is evenly distributed and lasts longer, reducing the need for frequent belt changes. Overall, using the appropriate grit size and high-quality sanding belts can help wood flooring contractors achieve a smooth and flawless finish on their projects.

When selecting sanding belts and discs for wood flooring contractors, several factors should be considered:

Grit size

Wood flooring contractors usually use a sequence of sanding belts with different grit sizes to achieve the desired finish. Coarser grits (lower numbers, e.g., 36 or 60) are used for initial sanding to remove old finish and imperfections. Finer grits (higher numbers, e.g., 80, 100, or 120) are employed for smoothing and preparing the floor for finishing.

Durability

Wood flooring contractors need sanding belts that can withstand heavy use and provide consistent performance throughout the refinishing process. Durable belts with strong backing material are preferred to avoid frequent replacements.

Dust extraction

Sanding wood generates a significant amount of dust. Look for sanding belts with good dust extraction capabilities to keep the work area cleaner and reduce the risk of airborne dust.

Compatibility

Ensure that the sanding belts are compatible with the specific belt sander used by the contractor. Different sanders have varying belt sizes and specifications.

Brand reputation

Opt for reputable brands known for producing high-quality sanding belts suitable for flooring contractors.

Belt type

There are different types of sanding belts available, such as cloth-backed or paper-backed belts. The choice depends on the specific needs and preferences of the contractor.

Some of the brands mentioned earlier, such as 3M, Norton, and Mirka, offer sanding belts suitable for wood flooring contractors. Additionally, specialized flooring suppliers may carry sanding belts tailored for flooring projects, so it’s worth exploring options from suppliers who cater to the flooring industry.

Lastly, safety is paramount when using sanding belts for wood flooring projects. Wood dust generated during sanding can be hazardous if inhaled, so wearing proper respiratory protection and ensuring good ventilation are essential precautions for the contractor’s health and safety.

Why are German Sanding Belts so good?

German sanding belts” that are universally recognized as superior or inherently better than sanding belts from other regions. It’s essential to clarify that the quality of sanding belts depends on various factors, including the brand, the materials used, manufacturing processes, and the specific application they are designed for.

However, Germany is known for its engineering and manufacturing excellence, and German companies have a reputation for producing high-quality industrial products, including abrasives and sanding belts. Several reasons might contribute to the perception of German sanding belts being of high quality:

Expertise and Innovation

German manufacturers often invest in research and development, leading to innovative techniques and advanced technologies used in the production of abrasives. Their expertise in engineering and materials science contributes to producing high-performance sanding belts.

Strict Quality Control

German companies are known for their rigorous quality control measures. They maintain high standards in the materials they use, manufacturing processes, and final product inspection, ensuring consistent quality and performance.

Durable Materials

German sanding belts may use high-quality abrasives and backing materials, making them more durable and effective in various applications.

Focus on Efficiency

German engineering often prioritizes efficiency and precision. As a result, German sanding belts may provide superior material removal and finishing capabilities compared to other products.

Industry Reputation

German brands that have been in the market for a long time and established a strong reputation for quality products may have an advantage in terms of perceived excellence.

German Sanding Belts are used by floor sanders, as these are the most hard wearing belts on the market, perfect for sanding down any wooden floors. Available in stock today for immediate delivery or collection at Parker Wade, please email or call: info@parkerwade.com / 01752 262469.

FREE DELIVERY:

ACCESSORIES OVER £200 & LAMINATE / LVT ORDERS OVER £1500, PLACED BEFORE 3.00 PM

GET IN TOUCH

Have an idea or project then please get in touch...